Against the backdrop of the fast fashion wave, the textile industry generates massive amounts of waste materials and carbon emissions every year. In 2024, approximately 1.2 billion tons of textile waste were produced globally, 80% of which was landfilled or incinerated, with less than 1% being recycled and reused. This not only represents a huge waste of resources but also imposes a heavy environmental burden.

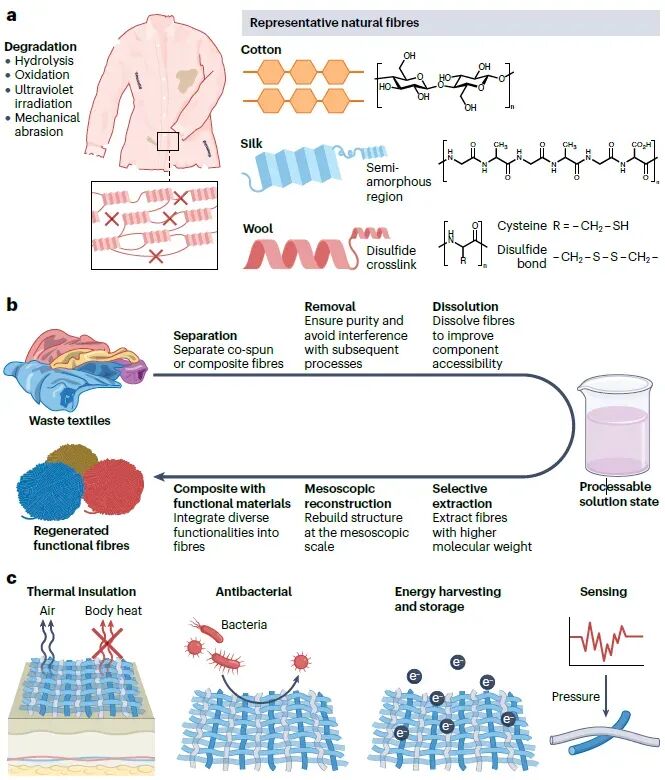

Notably, natural fibers such as cotton, silk, and wool account for about 31% of the world’s fiber production. These natural fibers hold significant potential for recycling and reuse. However, during the use and disposal of textiles, their structures tend to get damaged due to wear and tear, sunlight exposure, oxidative hydrolysis, and other factors. Moreover, the processing techniques involved in the recycling process may cause the breakage of their molecular chains and a decrease in molecular weight. Such performance degradation has severely hindered the recycling and application of natural fibers from textile waste.

In light of this, the research team led by Professor Ronghui Wu from Nanyang Technological University recently published a review article titled Upcycling textile waste into sustainable functional fibres in Nature Reviews Bioengineering. The article systematically elaborates on the cutting-edge technologies and immense possibilities of upcycling textile waste into high-value functional materials, pointing out the direction for a sustainable textile industry.

Current recycling methods for natural fibers in textiles mainly fall into three categories: mechanical recycling, chemical recycling, and enzymatic recycling.

- Mechanical recycling is the most straightforward method, which involves directly shredding waste fabrics into fibers. Its advantages lie in simplicity and low cost, but it severely impairs the length and strength of fibers, making it unfavorable for the development of high-value applications of the materials.

- Chemical recycling selectively degrades and separates different components through specific chemical reactions, and is particularly suitable for handling complex blended fabrics.

- Similarly, enzymatic recycling utilizes the high selectivity of enzymes to dissolve and extract natural polymers. This method features mild conditions and environmental friendliness, but compared with chemical recycling, it currently faces challenges such as higher costs and slower processing speeds.

The article points out that dyes and various functional additives widely used in textile production can severely interfere with the recycling process and affect the purity and performance of regenerated fibers. Therefore, developing efficient and eco-friendly separation technologies is the key to achieving sustainable management of textile waste.

In addition to recycling technologies, the article further focuses on the upcycling of natural fibers — that is, processing recycled materials into products with performance comparable to, or even more functional than, raw materials. For example, to address the limitation that “the reduced molecular weight of recycled fibers affects their mechanical properties”, high-molecular-weight components can be selectively extracted to prepare high-strength regenerated fibers. The feasibility of this strategy has been verified in relevant studies: by extracting heavy-chain fibroin from waste silk, the produced regenerated silk fibers exhibit tensile strength equivalent to that of natural silk and a higher modulus.

On this basis, mesoscale reconstruction can endow regenerated materials with unique mechanical, electrical, or optical properties. For instance, by precisely regulating the secondary structure of silk fibers through microfluidic spinning, the inherent hydrophilicity and hydrophobicity of silk can be converted into programmable humidity responsiveness, thereby enabling the fabrication of soft actuators with reversible contraction behavior.

Furthermore, combining fibers with functional nanoparticles can produce composite materials with new physicochemical properties, significantly expanding the functional applications of the materials:

- In the field of smart healthcare, treating silk with ionic liquids to attach silver nanoparticles enables the preparation of wound dressings and protective filters with excellent antibacterial properties.

- In the field of flexible sensing, combining zinc ferrite with regenerated silk fibroin via wet spinning yields fibers capable of detecting hydrogen peroxide, which can be used for physiological or environmental monitoring.

- In the energy sector, compounding tin oxide nanoparticles with waste cotton allows the manufacture of flexible, high-capacity supercapacitors to power wearable devices.

Based on the above processing and modification strategies, the article explores the possibility of upgrading waste natural fibers into high-functional devices, and further explores their application prospects from the perspective of the unique structural and performance characteristics of regenerated fibers (e.g., utilizing their intrinsic low-molecular-weight properties to incorporate them into high-molecular-weight systems as plasticizers to enhance material flexibility).

In practice, it is necessary to conduct in-depth research on various new technologies using Life Cycle Assessment (LCA) to ensure that the upcycling process has better environmental benefits than traditional treatment methods in terms of energy consumption and chemical usage.

Meanwhile, it is worth noting that achieving a true circular economy cannot only focus on end-of-life recycling and utilization. The article concludes with a more forward-thinking idea: Design for Circularity. At the very beginning of textile production, priority should be given to using single materials, reducing reliance on blended fabrics, and developing easily removable dyes and chemical treatment agents. These measures will not only simplify the recycling process and reduce costs but also help preserve the inherent excellent properties of natural fibers.

Post time: Jan-06-2026