Composite Fiber and Polyester/Nylon Composite Microfiber Production Technology

Composite fiber is formed by extruding melts of two or more polymers through the same spinneret orifice after being distributed by a special distribution plate. There are hundreds of types of composite fibers with various classification methods. Classified by production method, they are divided into composite spinning and blend spinning. Classified by spinning morphology, the five commonly used types are: conjugate type, side-by-side type, sheath-core type, splittable type, and sea-island type. Polyester/nylon composite fiber combines the advantages of nylon—wear resistance, high strength, easy dyeing and moisture absorption—with those of polyester—good elasticity, dimensional stability, stiffness and wrinkle resistance.

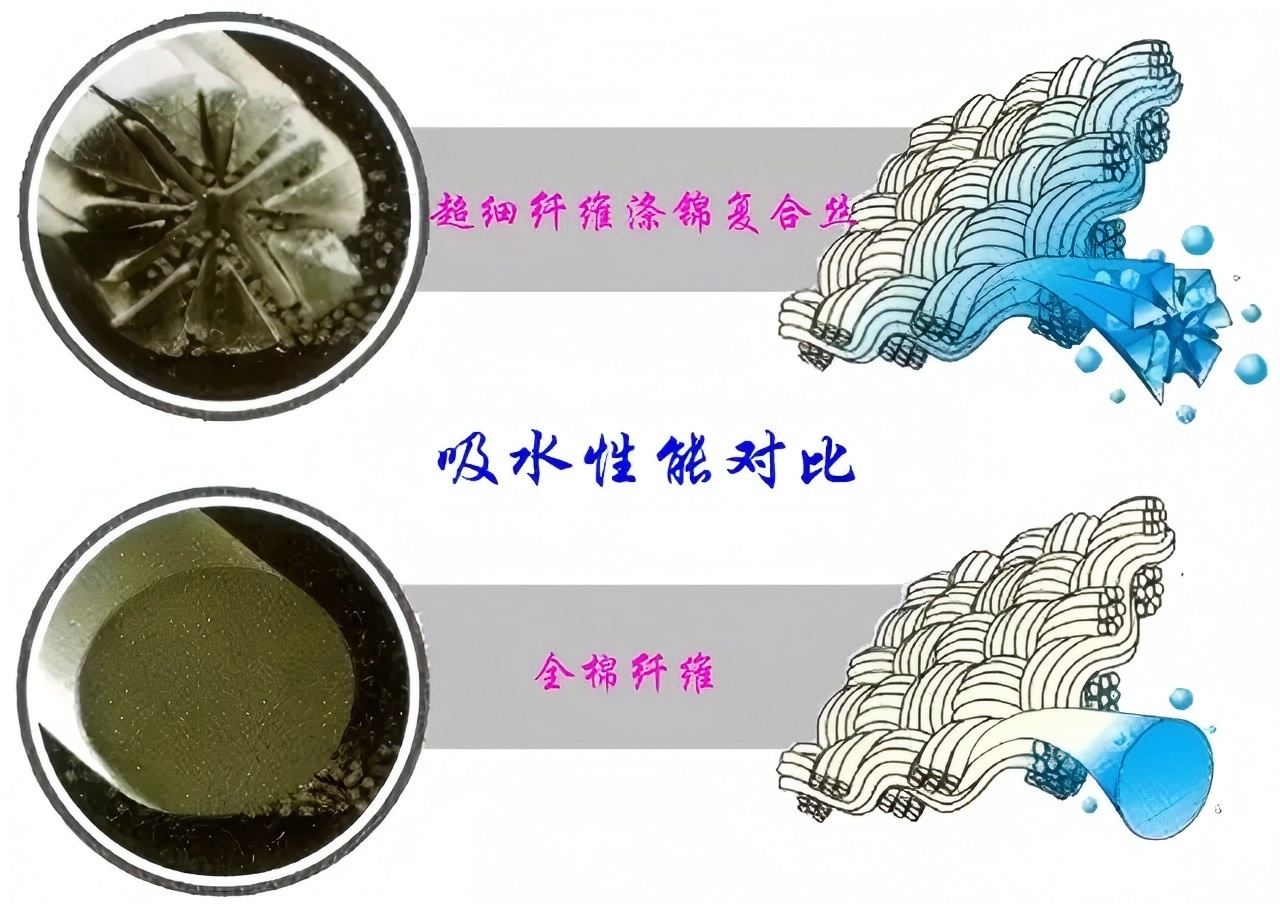

Most composite spinning processes focus on polyester/nylon composite fibers, which feature special-shaped cross-sections such as orange petal and rice-shaped profiles. These fibers exhibit excellent moisture absorption and are mainly used in cleaning products, home textile products and other applications. In addition, functional properties such as low melting point, flame retardancy, antistatic performance and electrical conductivity of many fibers are achieved through the special structure of composite spinning.

01 Production Methods of Polyester/Nylon Composite Microfiber

Polyester/nylon composite microfiber is produced via melt spinning of PET and PA polymers in a certain ratio, leveraging the differences in their chemical structures and weak interfacial adhesion that allows them to be separated from each other. Typically, antibacterial microfibers are manufactured by incorporating antibacterial agents into chemical fibers through blending or masterbatch addition to achieve long-lasting antibacterial effects.

Compared with post-finishing antibacterial technologies, antibacterial fibers offer superior and durable antibacterial performance. Fabrics made from these fibers have simplified weaving and dyeing processes, are free of resin deposits, and exhibit excellent hand feel. However, this production method involves high technical content and complexity, with particularly stringent requirements for antibacterial agents. Most organic antibacterial agents cannot withstand high temperatures and are unsuitable for melt spinning. In contrast, inorganic antibacterial agents—such as antibacterial phosphates, glass, ceramics and oxides—possess unique high-temperature resistance. They exert antibacterial and deodorizing effects primarily through the action of metal ions like silver, copper and zinc that they contain.

Domestic enterprises have applied composite antibacterial agents consisting of silver-containing inorganic phosphates and metal oxides in the production of polyester/nylon composite microfiber, adopting the technology of blend spinning with antibacterial masterbatch and fiber chips to produce antibacterial polyester/nylon composite microfibers and fabrics.

The antibacterial material used is an inorganic antibacterial agent (a mixture of silver-containing phosphate and metal oxides with 3% silver content and an average particle size of 400 nm). The spinning-grade resin chips include domestically produced ultra-fine denier nylon chips and ultra-fine denier polyester chips.

Melt spinning is carried out using the masterbatch addition method to produce melt-spun antibacterial polyester/nylon (80/20) composite microfiber. The antibacterial masterbatch is added to the polyester component at a ratio of approximately 2% relative to the base material. The process route adopts high-speed composite fiber spinning technology and the two-step POY-DTY process, resulting in fibers with excellent physical and mechanical properties. The average single filament fineness of fibers produced by this method is about 0.2 dtex, equivalent to 1/5–1/10 that of silk, which endows the fabric with excellent physical and chemical properties and facilitates its application in textile cleaning products and garment industry.

02 Application Technology Testing of Polyester/Nylon Composite Microfiber

Antibacterial performance tests were conducted separately on industrially produced antibacterial polyester/nylon composite microfiber DTY filaments and their dyed warp-knitted fabric products. The antibacterial tests were performed in accordance with the Japanese standard JIS L 1902, targeting Staphylococcus aureus, Klebsiella pneumoniae and Escherichia coli. The test results indicated that both the fibers and dyed fabric products met the blue and orange standard requirements of the Japan Fiber Evaluation Technology Council, demonstrating high antibacterial efficacy.

This finding confirms that the composite antibacterial agent composed of silver-containing inorganic phosphate and metal oxide micropowder can be applied in the industrial melt spinning production of antibacterial polyester/nylon composite microfiber filaments, thereby opening up a new approach for the production of functional and differentiated fibers. The antibacterial microfibers produced using this antibacterial masterbatch melt spinning technology and the two-step POY-DTY process exhibit excellent physical and mechanical properties and antibacterial effects, with feasible and reliable production processes and superior quality indicators of the finished warp-knitted fabrics. The industrially produced antibacterial microfibers effectively address the discoloration issue commonly associated with fibers made from inorganic antibacterial agents, and the color difference and yellowing index of the dyed products meet practical production requirements.

Batch production of warp-knitted fabrics using antibacterial polyester/nylon microfiber was carried out, and their dyeing and finishing processes were investigated. The dyed products showed excellent quality. Tests conducted under the ISO standard at 95°C demonstrated that the shrinkage rate and color fastness indicators met practical application requirements, with particularly outstanding shrinkage resistance.

In addition, a chemical fiber enterprise in Guangdong Province has successfully collaborated with Hills Company of the United States to retrofit a traditional polyester POY spinning production line with 12×8 positions. The retrofitted production line can also produce sea-island type and splittable type bicomponent composite fibers with stable and normal production operations, and the product quality fully complies with the required standards. The company has also established technical cooperation with relevant companies in South Korea and Taiwan, China, to retrofit traditional polyester POY spinning production lines for the production of single-component microfiber, aiming to achieve a single filament fineness of less than or equal to 0.35 dtex.

Thus, there is broad development potential for utilizing traditional polyester POY spinning production lines to produce antibacterial polyester/nylon composite microfiber filaments and fabrics.

03 Dyeing Properties of Polyester/Nylon Composite Microfiber

New synthetic fibers represented by microfibers exhibit significant differences in single filament fineness, cross-sectional morphology, surface morphology, shrinkage properties and polymer structure (chemical structure, crystallinity, orientation, etc.) compared with conventional synthetic fibers. Therefore, the spinning, weaving, dyeing and finishing processes of fabrics made from new synthetic fibers also differ considerably from those of conventional synthetic fiber fabrics.

Adding leveling agents during the dyeing process is an important approach to improve the dyeing properties of microfibers. Domestic enterprises have found that adding leveling agents to the dye bath can increase the solubility of disperse dyes in water, enhance the proportion of dyes in the monomolecular state, and help improve dyeing performance.

This indicates that leveling agents have a solubilizing effect on disperse dyes, i.e., increasing the amount of dyes in both monomolecular and micellar forms in the dye bath. Dyes in the monomolecular state are the main form for dye uptake by fibers, and micellar dyes release dye monomers more easily than dye crystals, both of which contribute to uniform dyeing.

Meanwhile, the presence of leveling agents also helps improve the high-temperature dispersion stability of disperse dyes, reducing the occurrence of dye streaks and specks. This is because microfibers have a large specific surface area and a high dye adsorption rate, which tend to cause uneven dyeing.

For antibacterial polyester/nylon composite microfiber filaments, the single filament specific surface area is not only large but also varies significantly, making it more prone to differences in dye uptake rates and consequently leading to dye streaks. Therefore, controlling the dye uptake rate is one of the key factors in dyeing microfibers with disperse dyes. Without adding leveling agents, the dye uptake curves of different disperse dyes vary greatly, resulting in dye streaks and color differences during dyeing. If the migration effect of disperse dyes is not obvious, these defects cannot be eliminated. Adding leveling agents can make the dye uptake curves of different disperse dyes more similar, which is very important for shade matching dyeing.

Researchers have found that an important mechanism by which leveling agents improve the dyeing properties of microfibers is by modifying the dye uptake curves of disperse dyes, reducing the differences between the dye uptake curves of different disperse dyes, and thereby enhancing the compatibility between dyes. This is crucial for shade matching dyeing, because when the dye uptake rates of the disperse dyes used for shade matching become basically consistent, it can ensure shade progression consistency, reduce the chance of color differences, and improve dyeing reproducibility.

Application of Polyester/Nylon Composite Microfiber

01 Pile Fabrics

Take peach skin velvet fabric as an example. After splitting, the low linear density of composite fibers enables the fabric to form extremely short microfiber fluff on the surface after sanding treatment. The fabric features a unique appearance and a warm, thick hand feel, making it a popular fabric in domestic and international markets in recent years. Compared with natural suede, artificial suede not only possesses the hand feel and appearance of natural suede, but also surpasses it in terms of lightness, thinness, dyeability, washability, wrinkle resistance and air permeability. Furthermore, it has mildew resistance, moth resistance and wash durability that natural suede cannot match. Artificial suede is mainly used in outerwear, jackets, golf gloves and upholstery fabrics.

02 Artificial Leather Manufacturing

Sea-island type composite staple fibers are produced by sea-island spinning, drawing and cutting of two fiber-forming polymers, which are then made into non-woven fabrics with a three-dimensional interlaced structure and subsequently treated with an impregnating solution formulated with polyurethane. After polyurethane coagulation, one component of the fiber is dissolved out to form microfibers or porous lotus root-shaped fibers. Different products can be obtained depending on whether a polyurethane foam layer is further coated on the surface, namely two-layer substrate structure leather and one-layer substrate structure leather. Finally, artificial leather products are obtained through surface treatments such as dyeing, coloring and embossing.

03 Silk-like Fabrics

Silk-like fabrics have extremely wide applications. After splitting treatment, polyester/nylon composite filaments, with their special-shaped cross-sections, varying linear densities and wicking moisture transport properties, impart the fabric with excellent hand feel, drapability and unique luster, and their wearing comfort and aesthetic appeal are superior to those of silk fabrics.

04 High-efficiency Cleaning Cloths

The surface of such fabrics is covered with microfibers and has a complex three-dimensional spatial structure, which enables them to absorb more liquid and dust and achieve satisfactory cleaning results without relying on any additional cleaning agents. They are the optimal cleaning cloths for eyeglass lenses, cameras and high-precision instrument lenses.

05 Fashion Fabrics

Since the emergence of microfibers has promoted the innovative development of the fashion industry, coupled with the wrinkle resistance of various blended fibers (with different linear densities, cross-sections and shrinkage rates), this type of artificial suede has been applied in a variety of products, such as high-end apparel, interior decoration, leather bags, shoes and many other products. Meanwhile, the development of new texturing technologies and special finishing technologies has enabled the production of fabrics with different styles using microfibers. The fabrics with dry hand feel, silk-like and wool-like textures can achieve the level of “ultra-fine simulation”. For example, the new synthetic fiber fabric “Cheey-Les he” produced by TORAY Company features softness, bulkiness, dry hand feel, light weight and warmth retention.

06 Knitted Fabrics

Network composite yarns are produced by composite networking of polyester/nylon microfilaments and cotton yarns, which are then used to develop knitted fabrics. After splitting, the single fiber diameter of microfibers is very small, so the number of fibers in the yarn of the same count is much higher than that of ordinary fibers, resulting in a much larger specific surface area of microfiber fabrics. Therefore, microfiber fabrics exhibit excellent moisture absorption and moisture transport properties, with soft hand feel and good drapability.

In addition, some fibers will break during the splitting process, and the fabric surface will be covered with a layer of short fiber fluff, resulting in a strong hairy feel. After composite networking with cotton yarn, the anti-pilling performance of microfibers is significantly better than that of ordinary filament fabrics, and the addition of cotton fibers also makes the fabric more comfortable and attractive to wear.

In terms of appearance, the fabric has obvious heathered luster effect. This type of fabric not only maintains the dimensional stability and wrinkle resistance of conventional polyester filament fabrics, but also possesses the moisture absorption and air permeability of cotton fibers, making it an ideal new type of knitted fabric, especially suitable for making T-shirts and casual wear, with broad market prospects.

07 Other Functional Fabrics

After splitting, polyester/nylon composite fibers form extremely fine fibers with special-shaped cross-sections, large specific surface area and unique interfacial properties, so they are widely used as high-performance absorbent face towels, quick-drying towels, filter materials and functional paper. Due to their fine single filament linear density, microfiber yarns become very compact due to the large number of fibers in the cross-section. By adopting appropriate fabric structures, the yarns can be made even more compact, thereby meeting the requirements of both windproof and breathable properties without any additional coatings or films.

In recent years, due to excessive capacity expansion in the polyester/nylon composite filament industry, the supply-demand relationship has reversed, and market conditions have undergone certain changes. However, with the increasing efforts of downstream enterprises in developing new products, polyester/nylon composite filaments still have certain development potential. For example, polyester/nylon/cotton composite fabrics can be used to make both men’s and women’s jackets and windbreakers, making them popular fabrics for winter.

Moreover, polyester/nylon composite microfibers can be developed to increase their added value. For instance, transfer printing on microfiber fabrics can overcome the uneven coloring problem caused by the particularly large fabric surface area, achieving high first-grade product rates and high dye transfer rates, with washing fastness reaching grade 3. However, from the perspective of wrinkle recovery properties, excessive reduction of single filament fineness will have a negative impact.

As the single filament becomes finer, the comprehensive mechanical properties of the fiber also change. Therefore, when considering single filament refinement, a comprehensive balance must be achieved to ensure maximum improvement in hand feel, so as to avoid sacrificing one aspect for another. When the degree of separation of polyester/nylon microfiber composite filaments in the fabric is high, the fabric has a soft hand feel; otherwise, the fabric hand feel becomes rough.

Due to the differences in properties between polyester and nylon, it is necessary to formulate targeted post-processing processes, which is also a prerequisite for the widespread application of polyester/nylon microfiber composite filaments.

Post time: Dec-22-2025