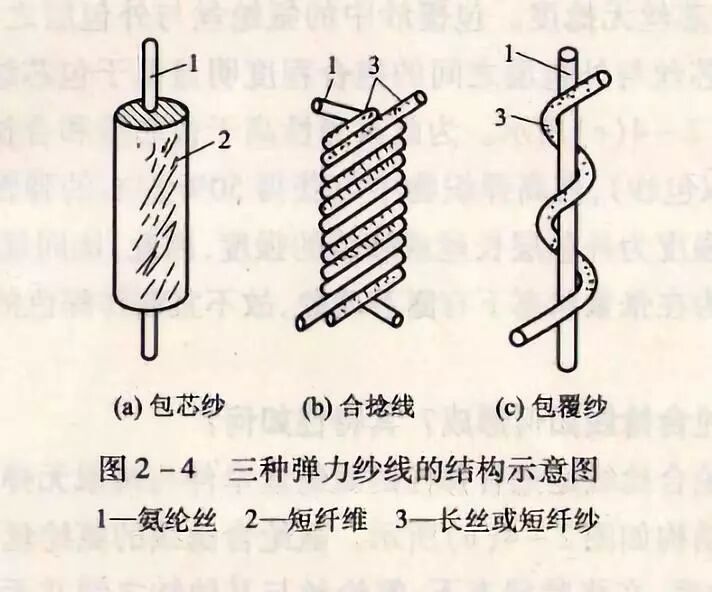

What are the forms of yarns made from spandex elastic fibers?

Spandex elastic fibers are blended with other fibers to produce stretch yarns, which currently come in three forms: spandex core-spun yarn, spandex twisted yarn, and spandex covered yarn. These three types of yarns are essentially different in terms of processing principles and structural properties. Therefore, they also vary significantly in their applications and weaving performance. The structural diagrams of the three yarn types are shown in the figure.

What is the origin and main properties of spandex fibers?

Spandex fiber is a type of elastic fiber, which is generally referred to as Spandex overseas. Its trade name in China is spandex, though technically, spandex is only a major category of elastic fibers. Spandex fiber (Polyurethane Fibre), abbreviated as PU fiber, has two varieties. One is a block copolymer composed of aromatic diisocyanate and hydroxyl-containing polyester segments, referred to as polyester-based spandex. The other is a block copolymer composed of aromatic diisocyanate and hydroxyl-containing polyether segments, referred to as polyether-based spandex. A representative trade name of polyester-based spandex is Vyrent, while a representative trade name of polyether-based spandex is Lycra.

The main properties of spandex fibers are as follows: it typically has an elongation of over 500%–700% with excellent elastic recovery. It retracts by 97% when stretched to 200%, and over 99% when stretched to 50%. The relative density of various spandex fibers varies slightly, generally ranging from 1.20 to 1.25. The breaking strength is 4.41–8.82 cN/tex (0.5–1.0 g/denier); polyester-based spandex has relatively low strength, while polyether-based spandex has higher strength. The moisture regain rate is generally 0.3%–1.2%, with multifilaments having a slightly higher moisture regain than monofilaments. It has good heat resistance—short-term storage at 95–150℃ will not damage the fiber, and the safe ironing temperature is below 150℃. The fiber burns slowly and forms a gel-like residue after combustion. It has excellent dyeability, can be dyed into various colors, and has strong affinity for dyes. It also has good acid and alkali resistance, can be bleached, and is mildew-resistant.

Why does spandex in denim lose its elasticity?

Low-stretch and high-stretch spandex core-spun yarns are increasingly used in denim fabrics, and the elasticity of spandex directly determines the progress of the denim washing process. In addition to poor inherent quality that makes spandex prone to elasticity loss, it is also affected by many external factors.

-

Enzyme powder in enzyme washing process

Enzyme powder is a multi-component compound, and differences in its internal chemical components can affect spandex elasticity loss, especially the anti-staining powder component. However, this phenomenon rarely occurs with high-quality enzyme powder.

-

Sodium hypochlorite (bleaching solution)

Spandex itself is not chlorine-resistant, so chlorine bleaching causes significant damage to spandex elasticity. Moreover, the concentration of bleaching solution, pH value, and reaction rate also play an important role in damaging spandex elasticity—heavy bleaching leads to greater damage.

Below are recommended solutions to mitigate spandex elasticity loss:

- For denim garments requiring chlorine bleaching, first treat them with 1–3 g/L of spandex chlorine bleaching anti-tendering agent SCL (1/10 of the bleaching solution dosage) in a water bath for 1–2 minutes, gradually heat the bath to 40℃, and add the bleaching solution in three batches: add 1/5 of the total amount first, then 2/5, and finally the remaining 2/5. Proceed according to the actual bleaching time.

- After bleaching, drain the bath while simultaneously adding water to gradually lower the temperature. This prevents rapid temperature drop, which could cause spandex embrittlement and elasticity loss.

-

Softening

Different auxiliaries manufacturers use different formulations for softeners and silicone oils. Some softeners and silicone oils contain small amounts of solvents in their components, which can damage spandex elasticity. High-quality silicone oils and softeners, however, are basically solvent-free and have no impact on spandex elasticity—examples include silicone oil TS-12 and amino silicone oil TS-GB-348.

-

Solvents

Silicone-based oils are used during spandex weaving and need to be removed during the dyeing and finishing process. Many scouring agents contain solvents, which cause significant damage to spandex elasticity.

-

Physical damage

A key characteristic of denim is its vintage style, so physical distressing and slitting treatments are often applied. These processes cause uneven stress on spandex elastic filaments, leading to spandex bubbling. Exposed yarns are also prone to breakage, resulting in elasticity loss.

-

Drying temperature

Generally, the drying temperature for denim fabrics containing spandex elastic filaments should be below 60℃. Excessively high temperatures will cause severe damage to spandex elasticity.

Post time: Dec-18-2025