100% Original 90*88/60*60 Cotton Lining Fabric - 98% cotton 2% Elastane 3/1 S Twill fabric 90*38/10*10+70D for outdoor garments, pants,etc. – Xiang Kuan

100% Original 90*88/60*60 Cotton Lining Fabric - 98% cotton 2% Elastane 3/1 S Twill fabric 90*38/10*10+70D for outdoor garments, pants,etc. – Xiang Kuan Detail:

| Art No. | MBT0436A1 |

| Composition | 98%Cotton2%elastane |

| Yarn Count | 10*10+70D |

| Density | 90*38 |

| Full Width | 57/58″ |

| Weave | 3/1 S Twill |

| Weight | 344g/㎡ |

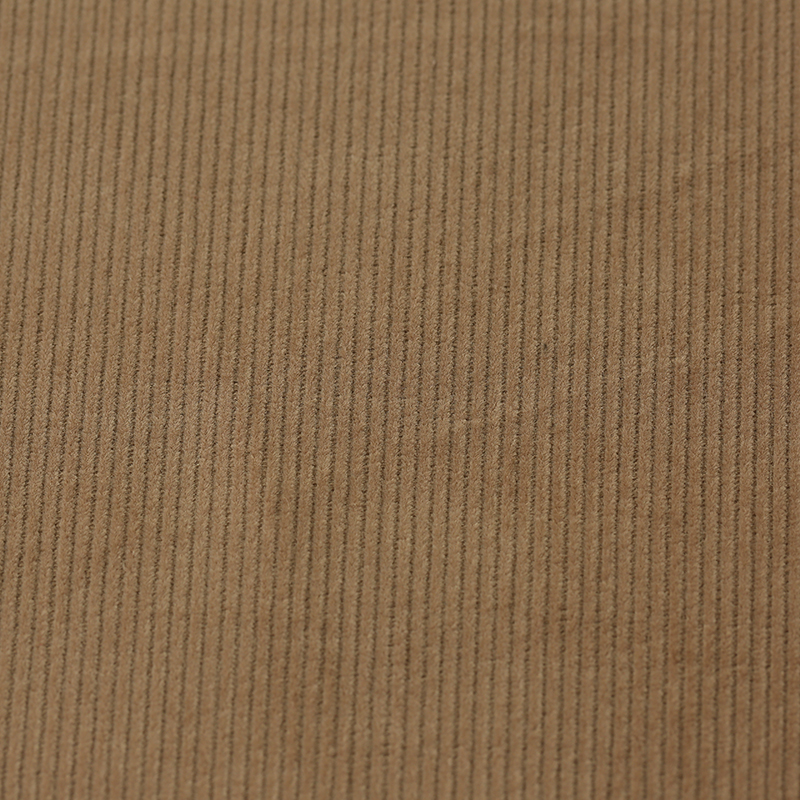

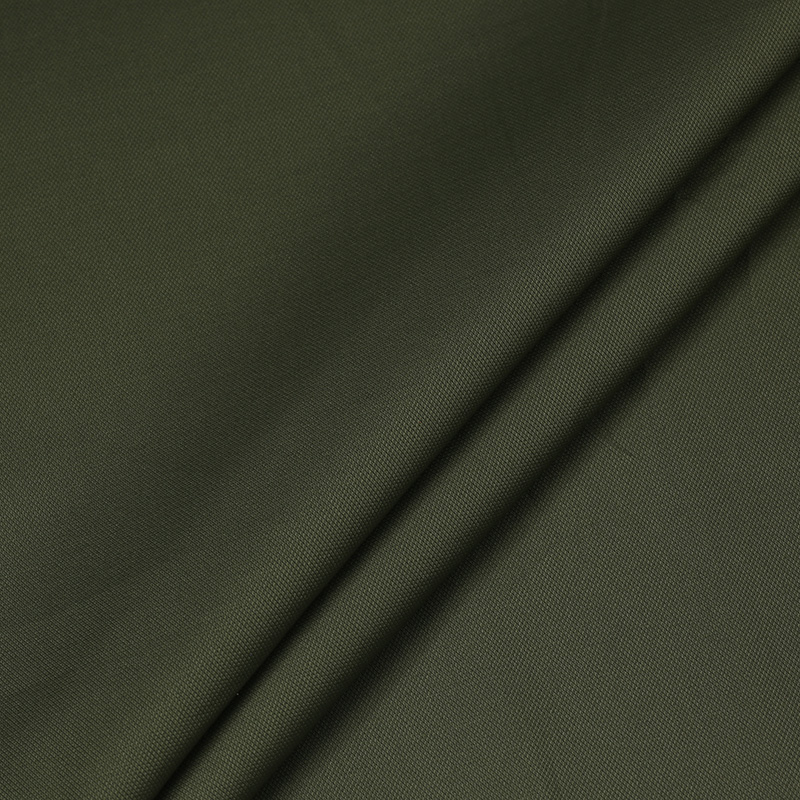

| Available Color | Dark Army, Black, Khaki,etc. |

| Finish | Regular |

| Width Instruction | Edge-to-edge |

| Density Instruction | Finished Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 25-30days |

| Supply Ability | 300,000 meters per month |

| End Use | Coat, Pants, Outdoor Garments, etc. |

| Payment Terms | T/T in advance, LC at sight. |

| Shipment Terms | FOB, CRF and CIF, etc. |

Fabric Inspection:

This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

How Is Elastane Fabric Made?

Four different methods can be used to produce this elastic fabric: Reaction spinning, solution wet spinning, melt extrusion, and solution dry spinning. Most of these production processes have been discarded as inefficient or wasteful, and solution dry spinning is now used to produce approximately 95 percent of the world’s spandex supply.

The solution dry spinning process begins with the production of a prepolymer, which serves as the basis of elastane fabric. This step is accomplished by mixing macroglycol with a diisocyanate monomer within a special type of reaction vessel. When the right conditions are applied, these two chemicals interact with each other to form a prepolymer. The volume ratio between these two substances is critical, and in most cases, a glycol to diisocyanate ratio of 1:2 is used.

When the dry spinning method is used, this prepolymer is then reacted with diamine acid in a process known as chain extension reaction. Next, this solution is diluted with a solvent to make it thinner and easier to handle, and it is then placed inside a fiber production cell.

This cell spins to produce fibers and cure the elastane material. Within this cell, the solution is pushed through a spinneret, which is a device that looks like a showerhead with lots of tiny holes. These holes form the solution into fibers, and these fibers are then heated within a nitrogen and solvent gas solution, which causes a chemical reaction that forms the liquid polymer into solid strands.

The strands are then bundled together as they exit the cylindrical spinning cell with a compressed air device that twists them. These twisted fibers can be made in a variety of thickness options, and every elastane fiber in apparel or other applications is actually made from many tiny strands that have undergone this twisting process.

Next, magnesium stearate or another polymer is used to treat the elastane material as a finishing agent, which prevents the fibers from adhering to each other. Lastly, these fibers are transferred to a spool, and they are then ready to be dyed or woven into fibers.

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for 100% Original 90*88/60*60 Cotton Lining Fabric - 98% cotton 2% Elastane 3/1 S Twill fabric 90*38/10*10+70D for outdoor garments, pants,etc. – Xiang Kuan, The product will supply to all over the world, such as: Swansea, Southampton, Nigeria, During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We are looking forward to customers from all over the world to join us to a wild cooperation.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!