Factory made hot-sale Olive Twill Fabric - 98% cotton 2% 3/1 S twill fire retardant and anti-static fabric 128*60/20A*16A for flame retardant protective clothing – Xiang Kuan

Factory made hot-sale Olive Twill Fabric - 98% cotton 2% 3/1 S twill fire retardant and anti-static fabric 128*60/20A*16A for flame retardant protective clothing – Xiang Kuan Detail:

| Art No. | MBF9337Z |

| Composition | 98%Cotton2%SA |

| Yarn Count | 20A*16A |

| Density | 128*60 |

| Full Width | 57/58″ |

| Weave | 3/1 S twill |

| Weight | 280g/㎡ |

| Available Color | Red, Navy, orange etc. |

| Finish | Flame Retardant, Fire Retardant, Anti-static |

| Width Instruction | Edge-to-edge |

| Density Instruction | Greige Fabric Density |

| Delivery Port | Any port in China |

| Sample Swatches | Available |

| Packing | Rolls, fabrics length less than 30 yards are not acceptable. |

| Min order quantity | 5000 meter per color,5000 meter per order |

| Production Time | 30-35days |

| Supply Ability | 200,000 meters per month |

End Use: Flame retardant protective clothing for metallurgy, machinery, forestry, fire protection and other industries

Payment Terms: T/T in advance, LC at sight.

Shipment Terms: FOB, CRF and CIF, etc.

Fabric Inspection: This fabric can meet GB/T standard, ISO standard, JIS standard, US standard. All the fabrics will be 100 percent inspected before shipment according to American four point system standard.

| Fabric Composition | 98%Cotton 2% SA(10mm lattice conductive wire) | ||

| Weight | 280g/㎡ | ||

| Shrinkage | EN 25077-1994 | Warp | ±3% |

| EN ISO6330-2001 | Weft | ±3% | |

| Color fastness to washing(After 5 washes) | EN ISO 105 C06-1997 | 4 | |

| Color fastness to dry rubbing | EN ISO 105 X12 | 3 | |

| Color fastness to wet rubbing | EN ISO 105 X12 | 2-3 | |

| Tensile strength | ISO 13934-1-1999 | Warp(N) | 1306 |

| Weft(N) | 754 | ||

| Tear strength | ISO 13937-2000 | Warp(N) | 29.8 |

| Weft(N) | 26.5 | ||

| Flame retardant performance index | EN11611;EN11612;EN14116 | ||

| Fabric Composition | 98%Cotton 2% SA(10mm lattice conductive wire) | ||

| Weight | 280g/㎡ | ||

| Shrinkage | EN 25077-1994 | Warp | ±3% |

| EN ISO6330-2001 | Weft | ±3% | |

| Color fastness to washing(After 5 washes) | EN ISO 105 C06-1997 | 4 | |

| Color fastness to dry rubbing | EN ISO 105 X12 | 3 | |

| Color fastness to wet rubbing | EN ISO 105 X12 | 2-3 | |

| Tensile strength | ISO 13934-1-1999 | Warp(N) | 1306 |

| Weft(N) | 754 | ||

| Tear strength | ISO 13937-2000 | Warp(N) | 29.8 |

| Weft(N) | 26.5 | ||

| Flame retardant performance index | EN11611;EN11612;EN14116 | ||

About fire retardant fabric

Among all fire hazards, textiles getting burnt are more due to its widespread use. Majority of fire accidents are associated with the burning of textiles. Cellulosics that is commonly used in garments are comfortable, but are more prone to inflammability. The weight and weave of the fabrics also decides its inflammability. Heavy and tight woven fabrics burn slowly than loosely woven fabrics. Flammability is important, particularly for textiles. A retardant finish is given to fabrics to prevent it from getting burnt.

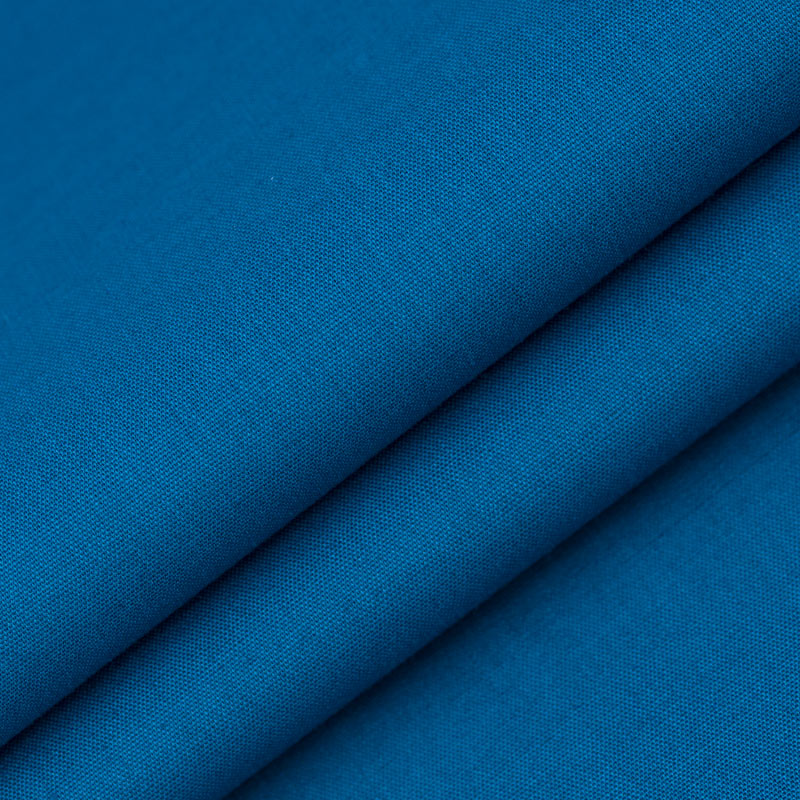

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory made hot-sale Olive Twill Fabric - 98% cotton 2% 3/1 S twill fire retardant and anti-static fabric 128*60/20A*16A for flame retardant protective clothing – Xiang Kuan, The product will supply to all over the world, such as: Lithuania, Nepal, Mauritania, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.